Double-Sided Tape Jumbo Roll: Everything You Need to Know

Double-sided tape jumbo roll is a versatile adhesive material that is used in a variety of applications. It is a type of tape that has adhesive on both sides, making it ideal for bonding two surfaces together. The jumbo roll size is particularly useful for large-scale projects that require a lot of tape.

One of the key benefits of double-sided tape jumbo roll is its ease of use. The tape can be easily cut to the desired length and applied to the surface without the need for any additional tools or equipment. It is also easy to remove and reposition if necessary, making it a popular choice for temporary applications.

Another advantage of double-sided tape jumbo roll is its strength. The adhesive is designed to bond to a wide range of surfaces, including metal, plastic, and wood. This makes it ideal for use in construction, automotive, and other industries where strong bonding is required. Overall, double-sided tape jumbo roll is a reliable and effective adhesive solution for a wide range of applications.

Overview of Double-Sided Tape Jumbo Rolls

Double-sided tape jumbo rolls are adhesive tapes with adhesive on both sides and are supplied in large rolls. These tapes are used in a variety of applications such as mounting, bonding, and splicing. The tapes are available in different widths, thicknesses, and adhesive strengths to suit different applications.

One of the advantages of double-sided tape jumbo rolls is their versatility. They can be used for bonding a wide range of materials such as plastics, cloth tape metals, fabrics, and paper. The tapes are also used in the automotive, construction, and electronics industries.

Double-sided tape jumbo rolls are easy to use and can be cut to any length required. The tapes are also easy to remove and do not leave any residue on the surface.

When selecting a double-sided tape jumbo roll, it is important to consider the application requirements such as the surface type, temperature, and humidity. It is also important to consider the adhesive strength required for the application.

Overall, double-sided tape jumbo rolls are a reliable and cost-effective solution for bonding and mounting applications.

Manufacturing Process

Materials Used

The manufacturing process of double-sided tape jumbo roll involves the use of various materials. The most common materials used for the backing of the tape include polyethylene, polypropylene, polyester, and PVC. These materials are chosen based on their strength, durability, and flexibility.

For the adhesive coating, manufacturers use either rubber-based or acrylic-based adhesives. Rubber-based adhesives offer high initial tack and good bonding strength, while acrylic-based adhesives provide excellent temperature resistance and long-term bonding.

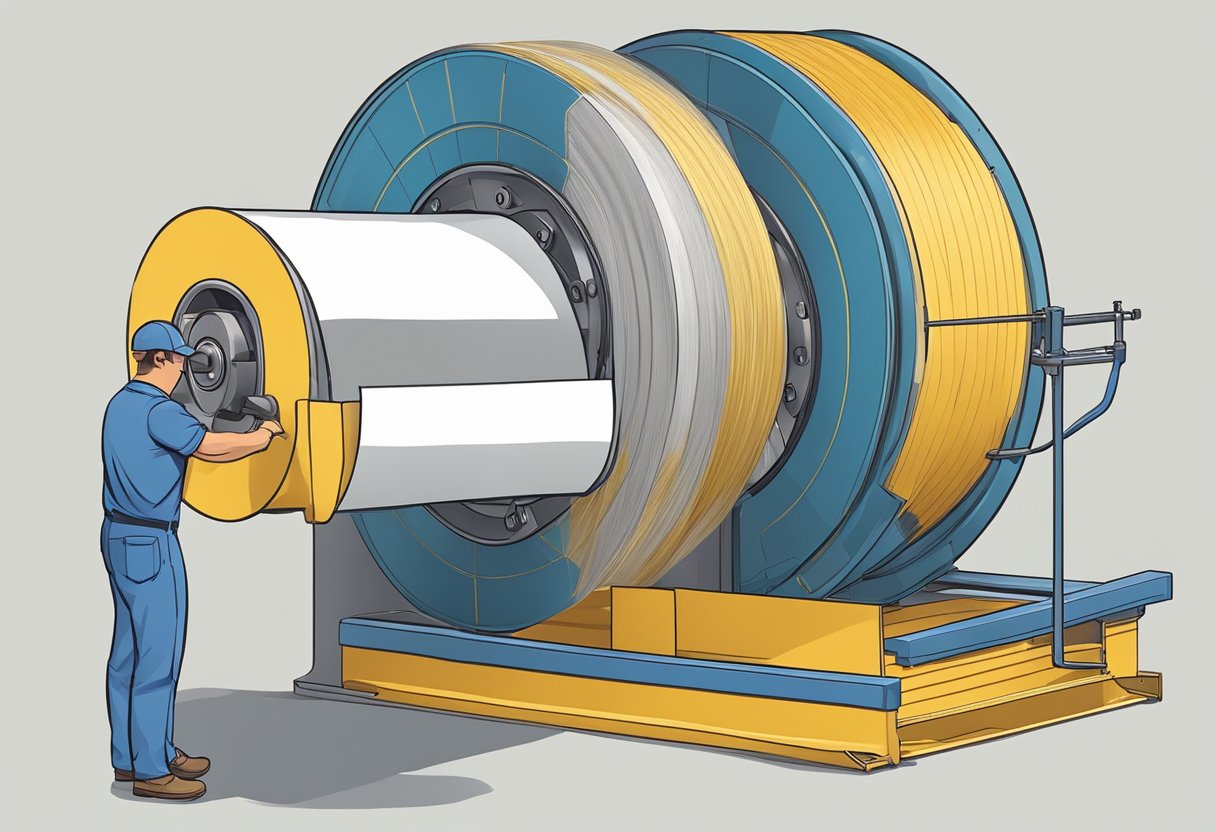

Adhesive Coating Techniques

After selecting the appropriate materials, the adhesive coating process begins. The adhesive is applied to one side of the backing material using various techniques, including hot-melt coating, solvent coating, and emulsion coating.

Hot-melt coating involves melting the adhesive and applying it to the backing material using a heated roller. Solvent coating involves dissolving the adhesive in a solvent and then applying it to the backing material. Emulsion coating involves mixing the adhesive with water and then applying it to the backing material.

Roll Cutting and Sizing

Once the adhesive is applied, the jumbo roll is cut into smaller rolls of various sizes. The rolls are then wound onto a core and packaged for shipment. The rolls can be customized to meet specific customer requirements, such as width, length, and color.

Overall, the manufacturing process of double-sided tape jumbo roll is a complex process that requires careful selection of materials and precise application of adhesive. The end result is a high-quality product that provides strong and long-lasting bonding.

Types and Specifications

Double-sided tape jumbo rolls come in various types and specifications to cater to different applications. In this section, we will discuss some of the common types and specifications of double-sided tape jumbo rolls.

Adhesive Strength

The adhesive strength of double-sided tape jumbo rolls can vary depending on the application. For example, a low-tack adhesive is suitable for temporary bonding, while a high-tack adhesive is ideal for permanent bonding. The adhesive strength is measured in ounces per inch (OPI) or grams per square meter (GSM). It is essential to choose the appropriate adhesive strength for your application to ensure the best performance.

Width and Length Variations

Double-sided tape jumbo rolls come in different widths and lengths. The width of the tape can range from 1/8 inch to 54 inches, while the length can vary from 36 yards to 1000 yards. It is crucial to select the appropriate width and length for your application to ensure maximum efficiency and minimum waste.

Material Compatibility

Double-sided tape jumbo rolls are compatible with various materials, including paper, plastic, metal, and glass. However, it is essential to consider the compatibility of the tape with the surface it is being applied to. For example, some tapes may not adhere well to oily or dirty surfaces, while others may not bond well to rough or uneven surfaces.

In conclusion, double-sided tape jumbo rolls come in various types and specifications to cater to different applications. It is crucial to choose the appropriate adhesive strength, width and length, and consider the material compatibility to ensure the best performance.

Applications and Uses

Double-sided tape jumbo roll is a versatile adhesive tape that can be used in a variety of applications. This section will highlight some of the most common uses of double-sided tape jumbo roll.

Industrial Applications

In industrial settings, double-sided tape jumbo roll is often used to bond materials together. It is particularly useful in applications where a strong, permanent bond is required. Double-sided tape jumbo roll can be used to bond metal, plastic, wood, and other materials. It is also commonly used in the automotive industry to attach trim and other components to vehicles.

Commercial Uses

Double-sided tape jumbo roll is also commonly used in commercial settings. It can be used to mount signs, posters, and displays. It is also useful for attaching carpet tiles and other flooring materials. In the packaging industry, double-sided tape jumbo roll can be used to seal boxes and other containers.

Home and DIY Projects

Double-sided tape jumbo roll is a popular choice for home and DIY projects. It can be used to hang pictures, mirrors, and other decorations without damaging walls. It is also useful for attaching trim and molding. Double-sided tape jumbo roll can be used to secure rugs and other floor coverings. It is also a popular choice for crafting and scrapbooking projects.

Overall, double-sided tape jumbo roll is a versatile and reliable adhesive tape that can be used in a wide range of applications. Its strength and durability make it a popular choice for industrial and commercial settings, while its ease of use and versatility make it a favorite among DIY enthusiasts and hobbyists.

Installation Guide

Surface Preparation

Before applying the double-sided tape jumbo roll, it is important to prepare the surface properly. The surface should be clean, dry, and free of any dust, oil, or debris. If the surface is not clean, the tape may not adhere properly, and the bond may fail.

To clean the surface, use a clean cloth or sponge and a mild detergent solution. Rinse the surface thoroughly with clean water and allow it to dry completely before applying the tape.

Application Techniques

When applying the double-sided tape jumbo roll, it is important to use the right technique to ensure a strong bond. Here are some tips to follow:

- Cut the tape to the desired length using a sharp pair of scissors or a knife.

- Peel off the protective liner from one side of the tape.

- Apply the exposed side of the tape to the surface, pressing down firmly to ensure good contact.

- Peel off the protective liner from the other side of the tape.

- Apply the second surface to the exposed side of the tape, pressing down firmly to ensure a strong bond.

- Use a roller or a similar tool to apply pressure evenly across the surface to ensure a strong bond.

- Allow the bond to set for at least 24 hours before subjecting it to any stress or load.

By following these simple tips, you can ensure a strong and long-lasting bond with the double-sided tape jumbo roll.