Electrical Insulation Green PET Protection Tape: Benefits and Applications

Electrical insulation is a crucial component of any electrical system. It protects against electrical shock and helps prevent damage to equipment. One type of electrical insulation that has gained popularity in recent years is green pet protection tape. This tape is made from a unique material that provides excellent insulation properties while also being environmentally friendly.

Green pet protection tape is made from a special type of polyester film that is coated with a silicone adhesive. This material is highly resistant to heat, moisture, and chemicals, making it ideal for use in a wide range of applications. It is also highly flexible, which makes it easy to apply to a variety of surfaces.

One of the key benefits of green pet protection tape is its environmental friendliness. Unlike other types of electrical insulation, which may contain harmful chemicals or be difficult to recycle, this tape is made from materials that are both safe and sustainable. This makes it an excellent choice for companies and individuals who are looking to reduce their environmental impact while still maintaining high levels of performance and safety in their electrical systems.

Overview of Electrical Insulation

Electrical insulation is a crucial aspect of electrical engineering, as it ensures the safety and reliability of electrical systems. Electrical insulation materials are used to prevent the flow of electric current between conductors, or between a conductor and the ground. The most common types of electrical insulation materials are plastics, ceramics, and composites.

One of the key properties of electrical insulation materials is their dielectric strength, which is the maximum voltage that the material can withstand before breaking down and allowing current to flow. Dielectric strength is influenced by factors such as material composition, thickness, and temperature.

Another important property of electrical insulation materials is their resistance to moisture and other environmental factors. Moisture can reduce the dielectric strength of some materials, leading to electrical breakdown. Therefore, it is essential to choose the right electrical tape insulation material for the specific application and environment.

Green PET protection tape is a type of electrical insulation tape that provides excellent dielectric strength and moisture resistance. It is made from a polyester film coated with a silicone adhesive, which provides a strong and durable bond. Green PET protection tape is widely used in the electrical industry for insulating and protecting wires and cables.

Overall, electrical insulation plays a critical role in ensuring the safety and reliability of electrical systems. By choosing the right insulation material for the specific application and environment, engineers can ensure that electrical systems operate efficiently and safely.

Properties of Green PET Protection Tape

Green PET Protection Tape is a type of electrical insulation tape that is designed to protect wires and cables from environmental factors such as moisture, dust, and abrasion. Here are some of the key properties of this tape:

- Material: Green PET Protection Tape is made from a polyester film that is coated with a silicone adhesive. This material is highly resistant to heat, chemicals, and UV radiation, making it ideal for use in harsh environments.

- Thickness: The thickness of Green PET Protection Tape can vary depending on the specific application. Generally, this tape is available in thicknesses ranging from 0.06mm to 0.15mm.

- Temperature Range: This tape is designed to withstand temperatures ranging from -40°C to 130°C, making it suitable for use in a wide range of applications.

- Tensile Strength: Green PET Protection Tape has a high tensile strength, which means that it can withstand significant amounts of stress without breaking or tearing.

- Dielectric Strength: This tape has a high dielectric strength, which means that it can withstand high voltage without breaking down or conducting electricity.

- Color: As the name suggests, Green PET Protection Tape is available in a green color. This makes it easy to identify and differentiate from other types of tape.

Overall, Green PET Protection Tape is a reliable and durable option for protecting electrical components in harsh environments. Its high resistance to temperature, chemicals, and UV radiation make it ideal for use in a wide range of applications.

Environmental Benefits of Green Insulation Tape

Green insulation tape offers several environmental benefits over traditional insulation tapes. Firstly, it is made from biodegradable materials, which means it breaks down naturally over time and does not contribute to landfill waste. This is a significant improvement over traditional insulation tapes, which are often made from non-biodegradable materials and can take hundreds of years to decompose.

Secondly, green insulation tape is free from harmful chemicals and toxins. Traditional insulation tapes often contain substances like PVC, which can release harmful chemicals into the environment during production, use, and disposal. Green insulation tape, on the other hand, is made from natural materials like paper and plant-based adhesives, which are safe for both humans and the environment.

Finally, green insulation tape is energy-efficient. It is designed to provide superior insulation properties, which means it can help reduce energy consumption and greenhouse gas emissions. By using green insulation tape, individuals and organizations can reduce their carbon footprint and contribute to a more sustainable future.

Overall, green insulation tape offers a range of environmental benefits that make it an excellent choice for individuals and organizations looking to reduce their impact on the environment. With its biodegradable materials, lack of harmful chemicals, and energy-efficient properties, green insulation tape is a smart and sustainable choice for any application that requires electrical insulation.

Applications in Electrical Insulation

Green PET protection tape is a versatile and reliable electrical insulation solution. It is widely used in various applications, including:

- Electrical wiring and cable harnessing

- Motor and transformer insulation

- PCB masking and protection

- Coil winding and bundling

The tape’s excellent electrical properties, such as high dielectric strength and low dielectric constant, make it an ideal choice for electrical insulation. Additionally, its green color provides easy identification and differentiation from other tapes.

The tape’s high tensile strength and temperature resistance make it suitable for use in harsh environments. It can withstand temperatures up to 130°C and is resistant to most chemicals, including solvents and oils.

Green PET protection tape is easy to apply and remove, making it a popular choice for both industrial and DIY applications. It is available in various widths and thicknesses to suit different requirements.

In summary, green PET protection tape is a reliable and versatile electrical insulation solution that finds applications in various industries. Its excellent electrical properties, high tensile strength, and temperature resistance make it an ideal choice for electrical insulation.

Manufacturing Process of Green PET Tape

Green PET tape is a type of electrical insulation tape that is widely used in various industries. The manufacturing process of green PET tape involves several steps, including:

- Raw Material Selection: The first step in the manufacturing process is the selection of raw materials. Green PET tape is made from polyethylene terephthalate (PET) film, which is a type of thermoplastic polymer. The PET film used in the manufacturing process is of high quality and is sourced from reliable suppliers.

- Coating: Once the PET film is selected, it is coated with a pressure-sensitive adhesive. The adhesive used in green PET tape is made from a combination of natural rubber and synthetic resin. The coating process is done using a special machine that ensures uniform coating thickness.

- Drying: After the coating process, the green PET tape is dried to remove any moisture content. The drying process is done in a controlled environment to ensure that the tape does not get damaged.

- Slitting: Once the tape is dried, it is slit into various widths and lengths. This process is done using a slitting machine that ensures accurate cutting of the tape.

- Packaging: The final step in the manufacturing process is packaging. The green PET tape is packaged in rolls of various lengths and widths, depending on the customer’s requirements. The rolls are then packed in boxes and shipped to the customers.

Overall, the manufacturing process of green PET tape is a complex process that requires precision and attention to detail. The use of high-quality raw materials and advanced machinery ensures that the final product meets the required standards of quality and reliability.

Standards and Compliance for Electrical Insulation Tapes

Electrical insulation tapes are subject to various standards and compliance requirements to ensure their safety and efficacy. These standards and regulations are put in place to protect both the user and the environment.

One of the most important standards for electrical insulation tapes is the UL 510 standard. This standard is issued by Underwriters Laboratories, an independent organization that tests and certifies products for safety. A tape that meets the UL 510 standard has been tested for its electrical and mechanical properties, as well as its resistance to fire and temperature.

Another important standard is the RoHS directive, which restricts the use of certain hazardous substances in electrical and electronic equipment. Electrical insulation tapes that comply with RoHS are free from substances such as lead, mercury, and cadmium, which can be harmful to human health and the environment.

In addition to these standards, electrical insulation tapes may also need to comply with specific industry regulations. For example, tapes used in the aerospace industry may need to meet the requirements of the FAA (Federal Aviation Administration) or the MIL-PRF-810G standard.

It is important to ensure that the electrical insulation tape being used meets the necessary standards and regulations for the intended application. Failure to comply with these standards can result in safety hazards, legal issues, and damage to equipment.

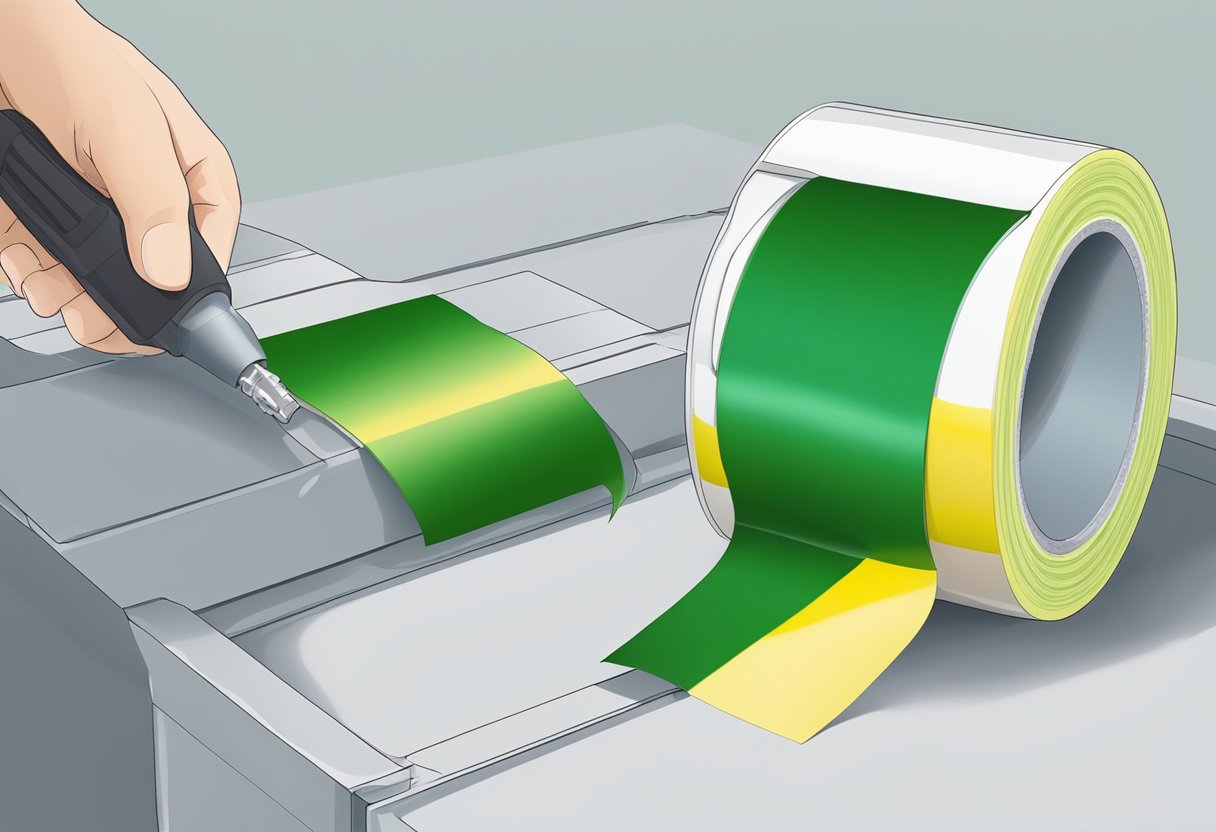

Installation Techniques for PET Protection Tape

PET Protection Tape is an excellent electrical insulation material that provides superior protection for electrical wires and cables. Here are some installation techniques that can help ensure a successful installation:

1. Surface Preparation

Before installing PET Protection Tape, it is important to ensure that the surface is clean and free of any dust, dirt, or debris. This can be done by wiping the surface with a clean, dry cloth or using a solvent to remove any contaminants.

2. Cutting the Tape

PET Protection Tape can be easily cut to the desired length using a pair of scissors or a sharp knife. It is recommended to cut the tape slightly longer than the length of the wire or cable to be wrapped to ensure complete coverage.

3. Wrapping the Tape

To wrap the wire or cable, start at one end and wrap the tape tightly around the wire or cable, overlapping each layer by about half the width of the tape. It is important to ensure that the tape is applied evenly and without any wrinkles or bubbles.

4. Finishing the Wrap

Once the wire or cable is completely wrapped, it is recommended to secure the end of the tape with a small piece of electrical tape or a wire tie. This will help prevent the tape from unraveling and provide additional protection.

PET Protection Tape is an easy-to-use and effective electrical insulation material that can provide long-lasting protection for your electrical wires and cables. By following these installation techniques, you can ensure a successful installation and protect your electrical system from damage.

Durability and Performance Metrics

Electrical insulation green pet protection tape is known for its high durability and excellent performance metrics. The tape is made of high-quality PET material that provides exceptional insulation, protecting electrical wires and cables from damage.

The tape’s durability is further enhanced by its resistance to moisture, chemicals, and UV radiation. This makes it ideal for use in harsh environments where other types of tape may fail to provide adequate protection.

In addition to its durability, the tape’s performance metrics are also noteworthy. It has a high dielectric strength, which means that it can withstand high voltage levels without breaking down. This makes it an ideal choice for use in high-voltage electrical applications.

Moreover, the tape’s adhesive properties are also excellent. It adheres well to a variety of surfaces, including plastic, metal, and rubber. This ensures that the tape stays in place, providing long-lasting protection to electrical wires and cables.

Overall, electrical insulation green pet protection tape is a reliable and high-performing solution for electrical insulation needs. Its durability and performance metrics make it an ideal choice for a variety of applications, from automotive to aerospace and beyond.

Safety Considerations in Handling and Use

When handling electrical insulation green pet protection tape, it is important to take certain safety precautions to avoid accidents and ensure proper use. Here are some safety considerations to keep in mind:

- Wear protective gear: When handling the tape, it is recommended to wear protective gear such as gloves and safety glasses to avoid skin irritation and eye damage.

- Avoid contact with water: The tape should not be used or stored in wet or damp conditions as this can compromise its performance and effectiveness.

- Store in a dry place: The tape should be stored in a dry place away from direct sunlight and heat sources to prevent degradation of the adhesive and backing material.

- Do not use on live circuits: The tape should not be used on live circuits or electrical equipment that is energized as this can cause electric shock or damage to the equipment.

- Follow manufacturer instructions: It is important to follow the manufacturer’s instructions for proper handling and use of the tape to ensure its effectiveness and longevity.

By following these safety considerations, users can ensure safe and effective use of electrical insulation green pet protection tape.

Recycling and Disposal of PET Insulation Tape

PET insulation tape is an environmentally friendly alternative to traditional PVC insulation tape. It is made from polyethylene terephthalate (PET), which is a recyclable material. PET insulation tape is designed to be used in a variety of applications, including electrical insulation, cable bundling, and wire harnessing.

When it comes to recycling PET insulation tape, it is important to note that it can be recycled along with other PET products. PET is a highly recyclable material, and it can be recycled multiple times without losing its quality. PET insulation tape can be recycled through curbside recycling programs or through specialized recycling centers that accept PET products.

PET insulation tape can also be safely disposed of in landfills. PET is an inert material that does not release harmful chemicals or gases when it decomposes. However, it is important to note that landfills should be the last resort for disposing of PET insulation tape. Recycling should always be the first choice when it comes to disposing of PET products.

In conclusion, PET insulation tape is an eco-friendly alternative to traditional PVC insulation tape. It is made from recyclable material and can be recycled multiple times without losing its quality. PET insulation tape can be safely disposed of in landfills, but recycling should always be the first choice when it comes to disposing of PET products.