Spray Pretaped Covering Masking Film: The Ultimate Solution for Easy and Clean Painting

Spray pretaped covering masking film is a popular tool used by professionals and DIY enthusiasts alike to protect surfaces during painting, construction, and other projects. This innovative product combines the convenience of pre-taped masking film with the added benefit of a spray applicator, making it easier and faster to apply than traditional masking methods.

The spray pretaped covering masking film is designed to adhere to surfaces and create a barrier against paint, dust, and debris. Its unique design allows for easy application and removal, without leaving any residue or damage to the surface. This makes it an ideal choice for protecting floors, walls, furniture, and other surfaces during home renovation projects or commercial construction work.

Overall, spray pretaped covering masking film is a versatile and convenient product that can save time and effort during painting and construction projects. Its ease of use and effectiveness make it a valuable tool for both professionals and DIY enthusiasts.

Overview of Spray Pretaped Covering Masking Film

Spray pretaped covering masking film is a popular tool used by professionals and DIY enthusiasts alike. It is a type of masking film that comes with an adhesive tape already attached to one edge, making it easy to apply and remove.

This type of masking film is commonly used in painting projects to protect surfaces that should not be painted, such as windows, trims, and door frames. It is also useful in protecting surfaces from dust, debris, and overspray during construction or renovation projects.

Spray pretaped covering masking film comes in various sizes and thicknesses, allowing users to select the appropriate type for their specific needs. Some are designed for indoor use only, while others are suitable for both indoor and outdoor use.

One of the advantages of spray pretaped covering masking film is that it is easy to apply and remove, saving time and effort. The adhesive tape ensures that the film stays in place during the painting or construction process, and can be removed without leaving any residue on the surface.

Overall, spray pretaped covering masking film is a convenient and practical tool for anyone looking to protect surfaces during painting or construction projects. Its ease of use and versatility make it a popular choice among professionals and DIY enthusiasts alike.

Types of Spray Pretaped Masking Films

Spray pretaped masking films are a popular choice among DIY enthusiasts and professional painters alike. These films are designed to protect surfaces from overspray and drips during painting projects. There are several types of spray pretaped masking films available in the market.

Pre-Taped Polyethylene Films

Pre-taped polyethylene films are made from a plastic material that is resistant to tearing and puncturing. These films are ideal for use on smooth surfaces such as walls, windows, and doors. They are easy to apply and remove, and they leave no residue behind. Pre-taped polyethylene films are available in various sizes and thicknesses to suit different painting projects.

Pre-Taped Paper Films

Pre-taped paper films are made from a combination of paper and adhesive material. These films are ideal for use on surfaces that require a bit of flexibility, such as curves and corners. They are easy to apply and remove, and they are also biodegradable. Pre-taped paper films are available in various sizes and thicknesses to suit different painting projects.

Pre-Taped Cloth Films

Pre-taped cloth films are made from a cloth material that is resistant to tearing and puncturing. These films are ideal for use on rough surfaces such as concrete, brick, and stucco. They are easy to apply and remove, and they are also reusable. Pre-taped cloth films are available in various sizes and thicknesses to suit different painting projects.

In conclusion, spray pretaped masking films are a great investment for anyone who wants to ensure a clean and professional finish to their painting projects. By choosing the right type of spray pretaped masking film for your project, you can save time and effort while achieving excellent results.

Applications and Uses

Spray pretaped covering masking film is a versatile and convenient product that can be used in a variety of applications. Here are a few examples of how this product can be used:

Automotive Industry

Spray pretaped covering masking film is commonly used in the automotive industry for masking off areas of a vehicle that should not be painted. This can include areas such as windows, trim, and other parts of the car that should remain unpainted. The film is easy to apply and can be cut to fit any shape or size, making it an ideal solution for masking off irregularly shaped areas.

Painting and Decorating

Painters and decorators also find spray pretaped covering masking film to be a useful tool. The film can be used to mask off areas of a room that should not be painted, such as windows, baseboards, and door frames. It can also be used to protect furniture and other items in the room from paint splatters and drips. The film is easy to apply and can be removed without leaving any residue, making it a convenient solution for protecting surfaces during painting and decorating projects.

DIY Projects

Finally, spray pretaped covering masking film is a great tool for DIY enthusiasts who are working on a variety of projects around the home. It can be used to protect floors, walls, and other surfaces from damage during construction or renovation projects. The film is also useful for protecting furniture and other items during moves or storage. With its easy application and clean removal, spray pretaped covering masking film is a must-have tool for any DIY enthusiast.

Advantages of Pretaped Masking Films

Pretaped masking films are a popular choice for professionals and do-it-yourselfers alike. They offer several advantages over traditional masking methods, including time efficiency, convenience, and reduced waste.

Time Efficiency

One of the biggest advantages of pretaped masking films is their ability to save time. With traditional masking methods, it can take a significant amount of time to apply tape and cover surfaces. Pretaped masking films eliminate this step by combining the tape and film into one product. This means that users can simply unroll the film and apply it to the surface, saving valuable time and increasing productivity.

Convenience

Pretaped masking films also offer a high level of convenience. Because the tape and film are combined, users don’t have to worry about the tape falling off or getting lost. Additionally, the film is easy to apply and remove, making the masking process much simpler. This convenience factor is especially important for those who are new to masking or who need to complete a masking project quickly.

Reduced Waste

Another advantage of pretaped masking films is that they can help reduce waste. Traditional masking methods often require the use of multiple products, such as tape, plastic sheeting, and paper. This can result in a significant amount of waste, as these products are often discarded after use. Pretaped masking films eliminate the need for these additional products, reducing waste and making the masking process more environmentally friendly.

In conclusion, pretaped masking films offer several advantages over traditional masking methods, including time efficiency, convenience, and reduced waste. These benefits make them a popular choice for professionals and do-it-yourselfers alike.

How to Apply Pretaped Masking Films

Surface Preparation

Before applying the pretaped masking film, it is important to properly prepare the surface to be covered. The surface should be clean, dry, and free of any dust, debris, or oil. If necessary, use a cleaning solution to remove any contaminants and allow the surface to dry completely before applying the film.

Film Application Techniques

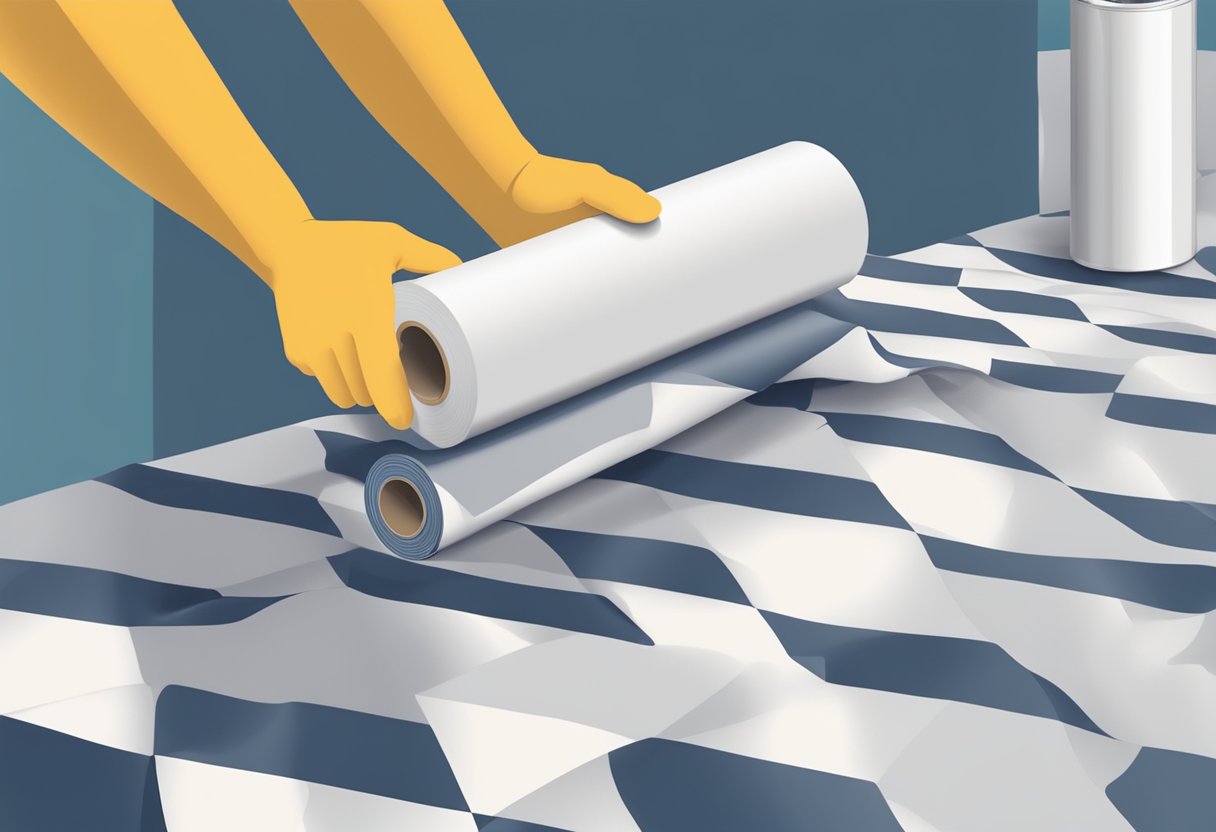

To apply the pretaped masking film, follow these simple steps:

- Measure and cut the film to the desired length.

- Peel off the backing paper from the tape edge of the film, exposing the adhesive.

- Apply the tape edge of the film to the surface, starting at one end and working your way to the other end.

- Smooth out any wrinkles or bubbles in the film as you go along, using a plastic squeegee or your hands.

- Once the tape edge is securely in place, unroll the film and press it down onto the surface, smoothing out any wrinkles or bubbles as you go along.

- Trim any excess film with a utility knife or scissors.

Removal and Disposal

When it is time to remove the pretaped masking film, simply pull it off the surface in one smooth motion. If any adhesive residue remains, use a cleaning solution to remove it.

Dispose of the used masking film in accordance with local regulations for waste disposal. Do not burn or incinerate the film.

Selecting the Right Masking Film

When it comes to spray painting, a good masking film is essential to ensure clean and sharp lines. Here are some factors to consider when selecting the right masking film for your project.

Adhesion Levels

One important factor to consider is the adhesion level of the masking film. A film with too little adhesion may not stick to the surface properly, leading to paint bleeding under the film. On the other hand, a film with too much adhesion may damage the surface when removed. It is important to choose a masking film with the right adhesion level for the surface being painted.

Film Size and Thickness

Another factor to consider is the size and thickness of the masking film. The film should be large enough to cover the entire area that needs to be protected, but not so large that it becomes difficult to handle. The thickness of the film should be appropriate for the job at hand. Thicker films may provide better protection, but they may also be more difficult to handle and remove.

UV Resistance

If the project involves outdoor painting, it is important to choose a masking film that is UV resistant. This will help prevent the film from breaking down and leaving behind residue when exposed to sunlight.

In conclusion, selecting the right masking film is crucial for achieving professional-looking results. Factors such as adhesion levels, film size and thickness, and UV resistance should be considered when choosing a masking film for your project.

Safety and Environmental Considerations

Health and Safety Precautions

When using spray pretaped covering masking film, it is important to take certain health and safety precautions to prevent any harm or injury. The following are some guidelines that should be followed:

- Always wear protective clothing such as gloves, goggles, and a mask to avoid getting the product on your skin, eyes, or lungs.

- Ensure that the area where the product is being used is well-ventilated to prevent the buildup of fumes.

- Keep the product away from heat sources and flames as it is highly flammable.

- If ingested or inhaled, seek medical attention immediately.

Environmental Impact

When considering the environmental impact of spray pretaped covering masking film, it is important to note that the product contains chemicals that can be harmful to the environment if not disposed of properly. The following are some guidelines that should be followed:

- Do not dispose of the product in regular trash as it can contaminate the soil and groundwater.

- Instead, dispose of the product at a designated hazardous waste disposal facility.

- Do not pour the product down the drain as it can pollute the water supply.

By following these guidelines, users of spray pretaped covering masking film can ensure that they are using the product safely and responsibly, while minimizing its impact on the environment.

Storage and Handling

Proper Storage Methods

When it comes to storing spray pretaped covering masking film, it is important to keep it in a cool, dry place. The film should be stored away from direct sunlight or any other sources of heat. Exposure to extreme temperatures can cause the adhesive to weaken, which can result in poor performance.

It is also important to store the film in its original packaging. This will help to protect it from dust, dirt, and other contaminants that could compromise its adhesive properties. If the film is not used immediately, it should be stored in a sealed container to prevent moisture from getting in.

Handling Best Practices

When handling spray pretaped covering masking film, it is important to avoid touching the adhesive side with bare hands. This can transfer oils and other substances from the skin onto the adhesive, which can reduce its effectiveness.

It is also important to handle the film gently to avoid damaging it. The film should be unrolled slowly and carefully to prevent it from tearing or becoming wrinkled. If the film does become wrinkled, it may not adhere properly to the surface it is being applied to.

Overall, proper storage and handling of spray pretaped covering masking film is crucial to ensure its effectiveness and performance. By following these best practices, users can ensure that the film is in good condition and will provide reliable protection during painting or other projects.