Stretch Film Hand Use: Tips and Techniques for Efficient Wrapping

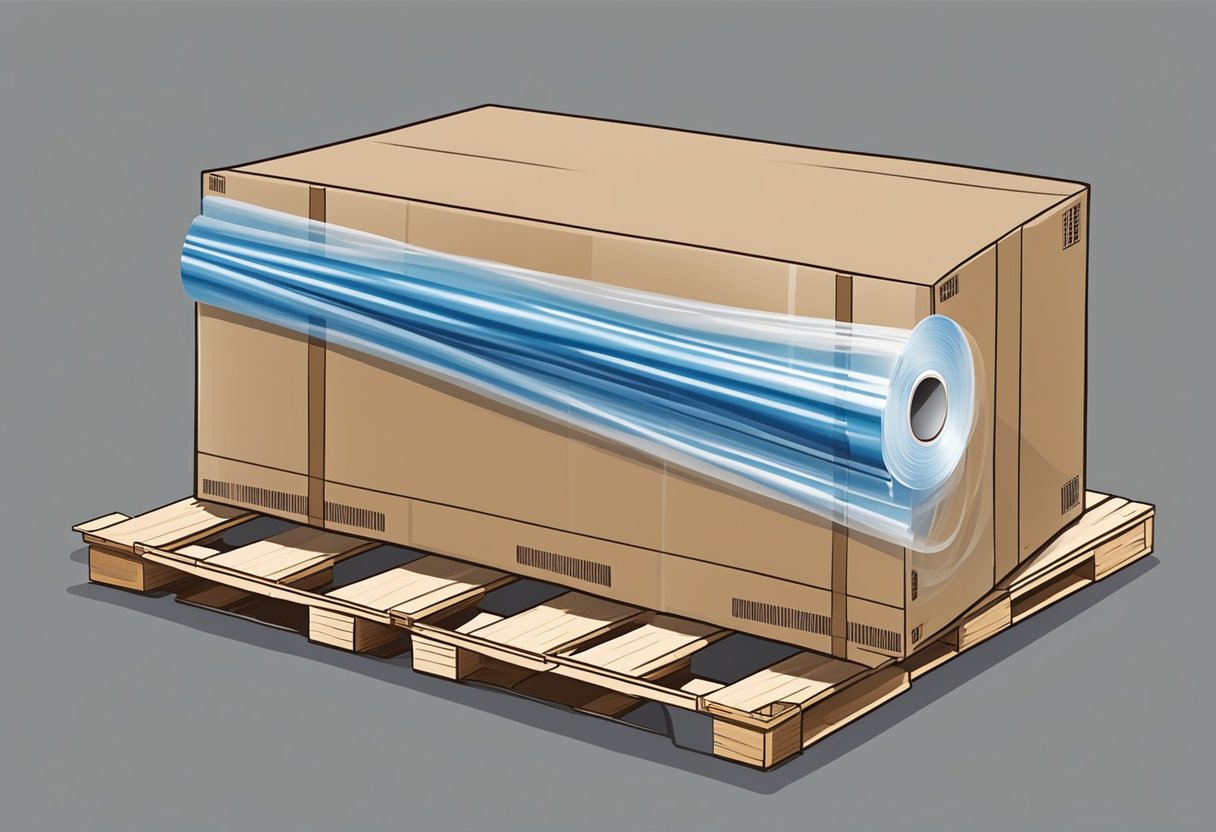

Stretch film hand use is an essential part of the packaging process for many industries. It is used to secure and protect items during transportation, storage, and handling. Stretch film is a versatile and cost-effective solution that provides excellent protection against moisture, dust, and other contaminants.

When it comes to stretch film hand use, there are several factors to consider. The first is the type of stretch film being used. There are different types of stretch film available, including cast, blown, and pre-stretched film. Each type has its own unique properties and benefits, and it is important to choose the right one for the job.

Another important factor to consider is the technique used to apply the stretch film. Proper technique can help to ensure that the stretch film is applied evenly and securely, providing maximum protection for the items being packaged. It is also important to use the right amount of stretch film, as using too little can result in inadequate protection, while using too much can be wasteful and inefficient.

Basics of Stretch Film

Stretch film is a highly stretchable plastic film that is commonly used to wrap and protect products during transportation or storage. It is made from linear low-density polyethylene (LLDPE) and is available in a variety of thicknesses, widths, and lengths.

The primary function of stretch film is to secure and protect products from damage during transit. It is also used to keep products clean and free from dust, moisture, and other contaminants. Stretch film is an economical and efficient way to protect products and reduce the risk of damage or loss.

Stretch film can be applied manually or with a machine. When applying stretch film by hand, it is important to use the correct technique to ensure that the film is applied evenly and tightly. The following tips can help ensure that stretch film is applied correctly:

- Start at the bottom of the load and work upwards.

- Pull the film tightly as it is wrapped around the load.

- Overlap the film by at least 50% to ensure that the load is fully covered.

- Apply several layers of film to ensure that the load is fully protected.

Stretch film is available in a variety of colors, including clear, black, and white. Clear stretch film is commonly used for applications where the contents of the load need to be visible. Black stretch film is used to protect products from UV light, while white stretch film is used to cover and protect products that are sensitive to heat.

In summary, stretch film is a versatile and cost-effective way to protect products during transit or storage. By using the correct technique and selecting the appropriate film for the job, products can be protected from damage and contamination, reducing the risk of loss or liability.

Types of Hand Stretch Film

Hand stretch film is a versatile packaging material that comes in various types. Each type of stretch film has unique properties that make it suitable for different applications. Here are some of the most common types of hand stretch film:

Cast Hand Stretch Film

Cast hand stretch film is a type of stretch film that is manufactured using a cast extrusion process. This process involves melting the resin and extruding it through a flat die onto a chill roll. Cast stretch film is known for its clarity, quiet unwind, and consistent stretch. It is an excellent choice for wrapping products with sharp edges or corners.

Blown Hand Stretch Film

Blown hand stretch film is produced using a blown extrusion process. This process involves blowing air into the center of a molten tube of resin to create a bubble. The bubble is then collapsed and flattened into a thin film. Blown stretch film is known for its toughness, puncture resistance, and cling. It is an ideal choice for wrapping heavy or irregularly shaped loads.

Pre-Stretched Hand Stretch Film

Pre-stretched hand stretch film is a type of stretch film that has been stretched during the manufacturing process. This stretching process reduces the thickness of the film while increasing its strength and elasticity. Pre-stretched stretch film requires less force to apply, reducing the risk of operator fatigue. It is also more cost-effective than traditional stretch film.

Colored Hand Stretch Film

Colored hand stretch film is a type of stretch film that comes in a variety of colors. It is often used for color-coding products or identifying different shipments. Colored stretch film is available in both cast and blown forms.

UVI Hand Stretch Film

UVI hand stretch film is a type of stretch film that contains UV inhibitors. These inhibitors protect the film and the products it wraps from the harmful effects of ultraviolet radiation. UVI stretch film is ideal for outdoor storage or transportation.

In conclusion, the type of hand stretch film you choose depends on the specific needs of your application. By understanding the different types of stretch film available, you can make an informed decision that will ensure the safe and secure transportation of your products.

Proper Techniques for Hand Wrapping

When it comes to hand wrapping with stretch film, there are a few proper techniques you should follow to ensure a secure and stable load. Here are some tips to keep in mind:

1. Start with a Clean and Dry Pallet

Before beginning the wrapping process, it’s crucial to make sure the pallet is clean and dry. Any debris or moisture on the pallet can cause the film to slip or tear, which can compromise the stability of the load.

2. Use the Right Amount of Film

Using too little film can result in an unstable load, while using too much can be wasteful and costly. It’s important to find the right balance and use just enough film to secure the load without overdoing it.

3. Apply Tension to the Film

Proper tension is key to achieving a secure wrap. Too little tension can result in a loose load, while too much can cause the film to stretch and tear. Applying even tension throughout the wrapping process will ensure a stable and secure load.

4. Overlap the Layers

Overlap the layers of film by at least 50% to ensure complete coverage of the load. This will help prevent any gaps or weak spots in the wrap that could lead to shifting or damage during transport.

5. Seal the Edges

Sealing the edges of the wrap is essential to prevent the film from unraveling during transport. Be sure to wrap the film around the edges of the load and tuck it under the previous layer to create a secure seal.

By following these proper techniques for hand wrapping with stretch film, you can ensure a secure and stable load for transport.

Safety Precautions for Hand Use

When using stretch film by hand, it is important to take certain safety precautions to avoid injuries and ensure the proper use of the product. Here are some tips to keep in mind:

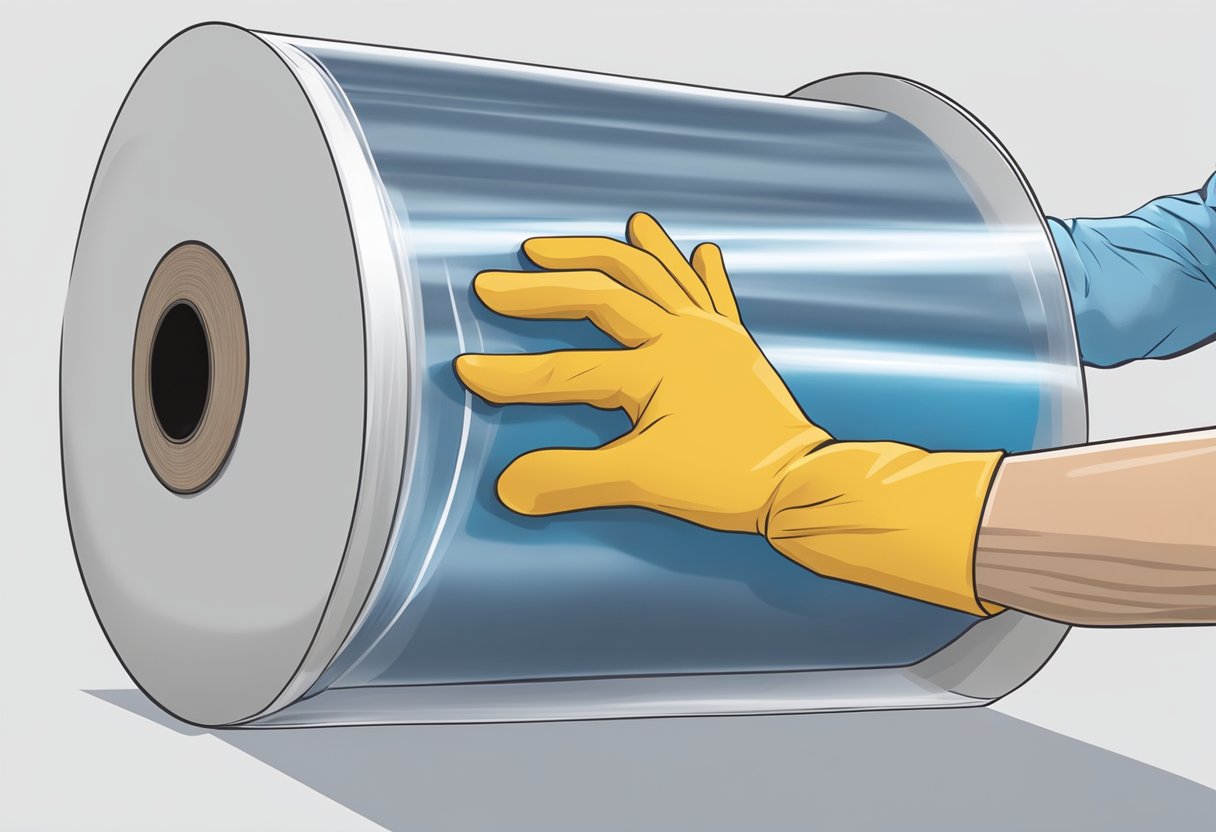

- Wear protective gloves to prevent cuts and abrasions while handling the film.

- Avoid overstretching the film, as it can cause it to tear or break, which can lead to injuries.

- Make sure to use the appropriate amount of tension when wrapping the product to avoid damage or deformation.

- Always use the proper size of the film to ensure that it covers the entire product and provides adequate protection.

- Keep the film away from heat sources, such as hot surfaces or direct sunlight, as it can cause the film to shrink or deform.

- Store the film in a cool, dry place to prevent it from becoming brittle or losing its elasticity.

By following these safety precautions, users can ensure that they are using stretch film by hand in a safe and efficient manner.

Equipment and Tools for Hand Stretch Wrapping

When it comes to hand stretch wrapping, having the right equipment and tools can make all the difference in ensuring a successful wrap. Here are some essential items to consider:

Stretch Film

The most important item for hand stretch wrapping is, of course, the stretch film itself. It’s important to choose a film that is appropriate for the load being wrapped and the conditions it will encounter during transportation and storage. Some common types of stretch film include:

- Cast stretch film: This type of film is made by extruding a thin layer of film onto a chill roll, which cools and solidifies the film. Cast film is known for its clarity and quiet unwind.

- Blown stretch film: Blown film is made by blowing melted resin through a circular die, which creates a bubble of film that is then cooled and collapsed. Blown film is known for its toughness and puncture resistance.

Dispensers

A dispenser can make a big difference in the ease and efficiency of hand stretch wrapping. There are a few different types of dispensers to choose from, including:

- Handheld dispensers: These are the most basic type of dispenser, consisting of a handle and a brake that controls the tension of the film.

- Extended core dispensers: These dispensers have an extended core that acts as a handle, making it easier to grip and apply the film.

- Mechanical dispensers: These dispensers use gears or other mechanisms to apply tension to the film, making it easier to wrap large or heavy loads.

Accessories

There are a few other accessories that can be helpful when hand stretch wrapping, including:

- Gloves: Wearing gloves can help protect your hands from cuts and abrasions while wrapping.

- Corner protectors: These plastic or cardboard pieces can be placed on the corners of a load to prevent the film from tearing or puncturing.

- Cutters: A cutter can make it easier to cut the film cleanly and quickly.

By using the right equipment and tools, hand stretch wrapping can be a quick and easy way to protect your products during transportation and storage.

Efficiency Tips for Hand Stretch Film Application

When using stretch film by hand, there are some efficiency tips that can help save time and effort. Here are some useful tips to keep in mind:

- Start by selecting the right type of stretch film for the job. Different films have different properties, such as thickness, stretchability, and clinginess. Choosing the right film for the job can help reduce waste and ensure better load stability.

- Make sure to use the correct amount of tension when wrapping the load. Too little tension can result in loose or shifting loads, while too much tension can cause film breakage or damage to the product. Using a tension control device or a pre-stretch film can help ensure consistent tension levels.

- Use a dispenser or a handle to make the wrapping process easier and more comfortable. This can help reduce operator fatigue and increase productivity. There are various types of dispensers available, such as handheld, tabletop, or freestanding models.

- Apply the film in a spiral pattern, overlapping each layer by at least 50%. This can help create a tight and secure wrap that can withstand the rigors of transportation and storage. Avoid gaps or wrinkles in the film, as they can weaken the wrap and increase the risk of damage.

- Take advantage of the film’s clinginess by using it to secure the load to the pallet. This can help eliminate the need for additional strapping or banding, which can be time-consuming and costly. However, be careful not to wrap the load too tightly, as it can cause compression damage or deformation.

By following these efficiency tips, hand stretch film application can be a quick and easy process that can help protect products during shipping and storage.

Common Mistakes in Hand Stretch Film Use

When it comes to hand stretch film use, there are a few common mistakes that people make. These mistakes can lead to decreased efficiency and increased waste. Here are some of the most common mistakes to avoid:

1. Overstretching the Film

One of the most common mistakes in hand stretch film use is overstretching the film. When the film is stretched too much, it can become thin and tear easily, which can lead to product damage and increased waste. It is important to use the right amount of tension when wrapping products to avoid overstretching the film.

2. Not Using Enough Film

Another common mistake is not using enough film. When there is not enough film used, the product may not be properly secured, which can lead to damage during transportation. It is important to use enough film to ensure that the product is properly wrapped and protected.

3. Wrapping Too Quickly

When wrapping products with hand stretch film, it is important to take the time to wrap them properly. Wrapping too quickly can lead to uneven tension and a poorly wrapped product. Take the time to wrap the product carefully and evenly to ensure that it is properly secured.

4. Using the Wrong Type of Film

Using the wrong type of film can also lead to problems. For example, using a film that is not strong enough for the product being wrapped can lead to tears and damage during transportation. It is important to use the right type of film for the product being wrapped to ensure that it is properly protected.

By avoiding these common mistakes, you can ensure that your hand stretch film use is efficient and effective, leading to reduced waste and increased product protection.