How to detect a good acrylic tape

In the process of research, development and production of acrylic tape, what aspects should a roll of high-quality tape be tested to ensure that the physical properties of the product are qualified? Here are some steps of FUJIAN YOUYI GROUP to test the tape products to ensure its physical properties are stable.

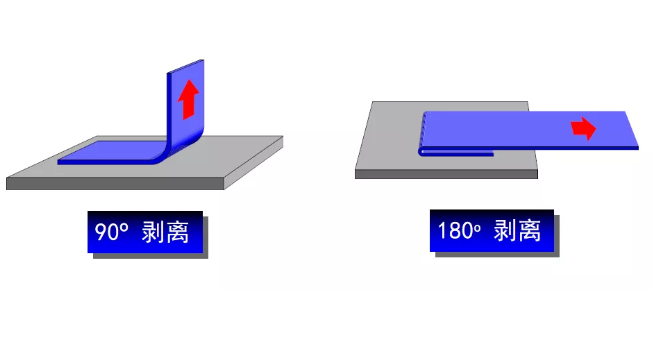

1、 Acrylic tape viscosity test – Dynamic peel strength test

The force required for the pressure-sensitive adhesive with a standard area to peel from the test plate at a specific speed and angle under a specific temperature environment. Generally, 90 ° peel force test and 180 ° peel force test are tested.

2、 Cohesion test of acrylic tape — static shear strength test

The time required for a standard area of pressure-sensitive tape to slide off the test plate after being loaded with a constant load under a specific temperature environment. The general standard test is 20 minutes and 72 hours.

3、 Cohesion test of acrylic tape — dynamic shear strength test

The force required when the pressure-sensitive adhesive with standard area slides from the test plate at a constant speed under a specific temperature environment.

4、 Initial adhesion test

Using the inclined rolling ball method, the initial viscosity of the sample is tested by the adhesion of the adhesive tape to the steel ball when the steel ball and the adhesive surface of the pressure-sensitive tape sample have a short contact with a small pressure.

5、 High temperature and humidity test

The high temperature and high humidity testing machine is applicable to the adaptability test of pressure-sensitive tape during storage, transportation and use in the high and low temperature alternating damp and heat environment. It is also a reliability testing equipment for cold resistance, heat resistance, humidity resistance and dry resistance tests of various raw materials and devices and quality control engineering.

6、 Tensile test (peel force, dynamic shear force)

Tensile tester is an instrument for tensile testing, which is mainly used for tensile, compression, bending, peeling, shearing and tearing tests of non-metallic materials such as adhesive tape, rubber, sea foam, waterproof materials, non-woven fabrics, and metal wires, metal foils,metal plates and metal rods.

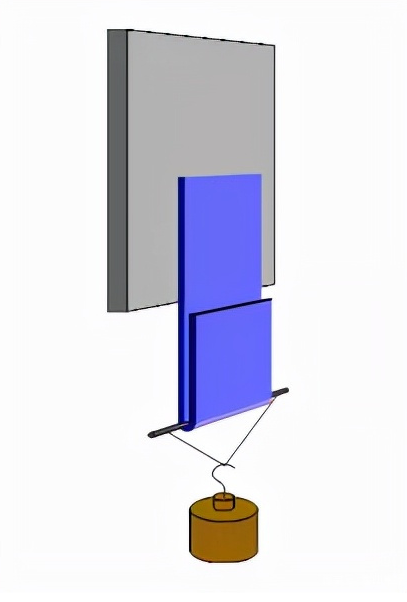

7、 Hanging weight test

Hang the test plate with acrylic tape vertically on the test frame, and hang a weight of the specified weight at the lower end. Use the displacement of the sample after a certain time, or the time of the sample completely separating, to ensure the ability of the adhesive tape to resist pulling off.

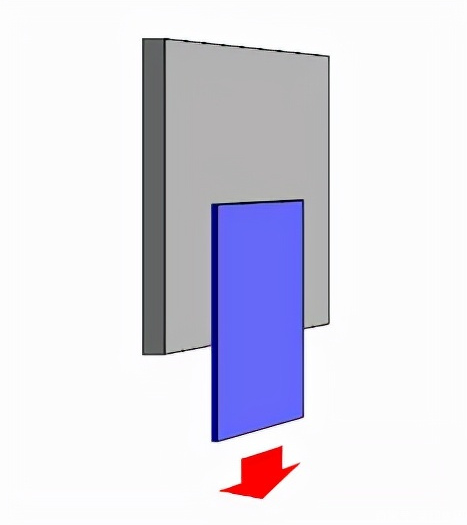

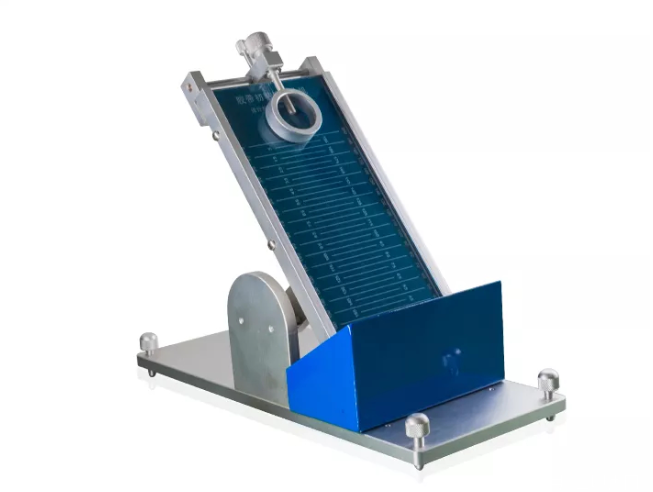

8、 Retention test

The principle of the tape retention tester: put the tape specimen in a hot environment to test the adhesive time of the tape.

The acrylic tape retention force tester conducts a static load test on the adhesive force of the tape. Under a certain load, it automatically counts the retention time of the tape to confirm the aging of the tape adhesion. Because the temperature in the box can be set, it can understand the retention force of the test piece in different environments.

The above testing methods are part of the testing of acrylic tape by FUJIAN YOUYI GROUP, not all of them. If you need to know the company’s products, please contact the official of FUJIAN YOUYI GROUP.